blown film machine parts name

Carmel Offers a broad Variety of blown film extrusion line for numerous diverse applications Like grocery bag T-Shirt bags mulch film grow bag garbage bag food Packaging Shipping Packaging film and many other using HM HDPE LDPE LLDPE as raw material. The plastic is then forced through a cylindrical die and forms a thin walled bubble.

Blown film lines are used to make shrink wrap films.

. 1160MM Non Woven Six Color Ci Flexo Printing Machine. What are the components of the film blowing machine. Static Eliminator 15KV 16KV.

3 Control over the angle and expansion of the main flow of air from the upper lip enabling adjustment of the low-pressure region that results in bubble lock. Blowing film involves a delicate balance of forces which are primarily controlled with the air ring lip settings. The traction motor of this unit adopts.

Blown film extrusion equipment is used in hundreds of industries around the world. The tubular film can then be slit to create a flat film or sealed at an end. 5 Layer Blown Film Co-ex Line Highly versatile die design leading to optimum quality of Barrier as well as Facilitates optimisation of Tie Layer Blown Film Co-extrusion Lines In Technical collaboration with.

SS Mechanical Engineers Pvt. By melting thermoplastic resins and inflating them a thin-walled tube is created. Please slide to verify.

BOPP PE Label Six Colors Central Drum Flexographic Ci Press Machine. Since 1987 Arlington Machinery has been a worldwide leader in plastics machinery equipment including blown film equipment and accessories. Film Widths up to 140 CALL US.

The film may be laminating film shrink film agricultural covering film bags or film for textiles and clothing and other packaging materials. The blown film process can produce a wide range of film sizes from the same die. The process of blown film is reasonably simple.

26Kw 1000mm HDPE Film Blowing Machine. Extruded tubular processing is most often used with polyethylene films but can be used with other polymers. 2 A suitable expansion angle leading to the upper lip and.

Open the catalog to page 10. Built Control Systems Engineering - Complete Spare Parts Inventory - Over 900 Complete Installations in North America. The traction auxiliary machine is composed of main comp The traction auxiliary machine is composed of main components such as traction frame herringbone plate traction roller take-up mechanism and traction motor.

This bubble is sustained by air and is fed up through a scaffold where the tube continues to rise. WINDSOR MACHINES LIMITED Formerly DGP Windsor India Ltd 5403 Phase IV GIDC Vatva Ahmedabad. Torque Control Board For Blown Film Extrusion.

Blown film towers require large vertical heights. First step plastic pellets are put into the extruder and heated to their melting point at 180 to 210 Celcius degree. Complete tutorial of mini film blowing machines - from startup to stable operationThis is a relatively long video about 10 minutes.

Filter Changer For Blown Film Extrusion. Our Products Extrusion Coating Lamination Plant. Plastic bag machinefilm blowing machine have spare partseach parts have limited life timesome parts can use 1 yearsome parts can use over 2 yearssome parts can use over 10 years.

Machine Direction Orientation MDO Both In-Line and Out-of-Line. 760MM Foil PVC UV Stack Six Color High Speed Ci Flexo Printing Machine. Sorry we have detected unusual traffic from your network.

55kg hr 0009mm HDPE Film Blowing Machine. 15 Davis Standard Blown Film Tower Model BTF. Whether You need Compact.

A film blowing machine involves one process used to make plastic film. 31Kw 1000mm Single Winder HDPE Monolayer Blown Film Machine. Blown films provide a better balance of properties between the machine and transverse directions.

What is Blown film Extrusion process in Hindi Blow ratio Draw Down Ratio PlasticsWorld alokrj cipet This video is for BTech BSc CIPET students. Yaskawa Servo Motor For Plastic Bag Machine. Our Products Extrusion Coating Lamination Plant.

- Started in MA in 1979 - Technical Sales Service for Blown Film Extrusion in North America - US. Blown film lines require lower melt temperatures. We maintain a rotating inventory of equipment for all steps in the blown film process including high-quality used machines from trusted manufacturers including Domino Ruli Mitsubishi Citcronix Kiefel.

Before the delivery of t.

Blown Film An Overview Sciencedirect Topics

Extruders An Overview Sciencedirect Topics

The Outline Of Injection Molding

Cast Film Extrusion An Overview Sciencedirect Topics

Direct Extrusion An Overview Sciencedirect Topics

Injection Molding Definition Process Parts Types Defects With Pdf

Extrusion An Overview Sciencedirect Topics

Plastic Extrusion What Is It How Does It Work Process

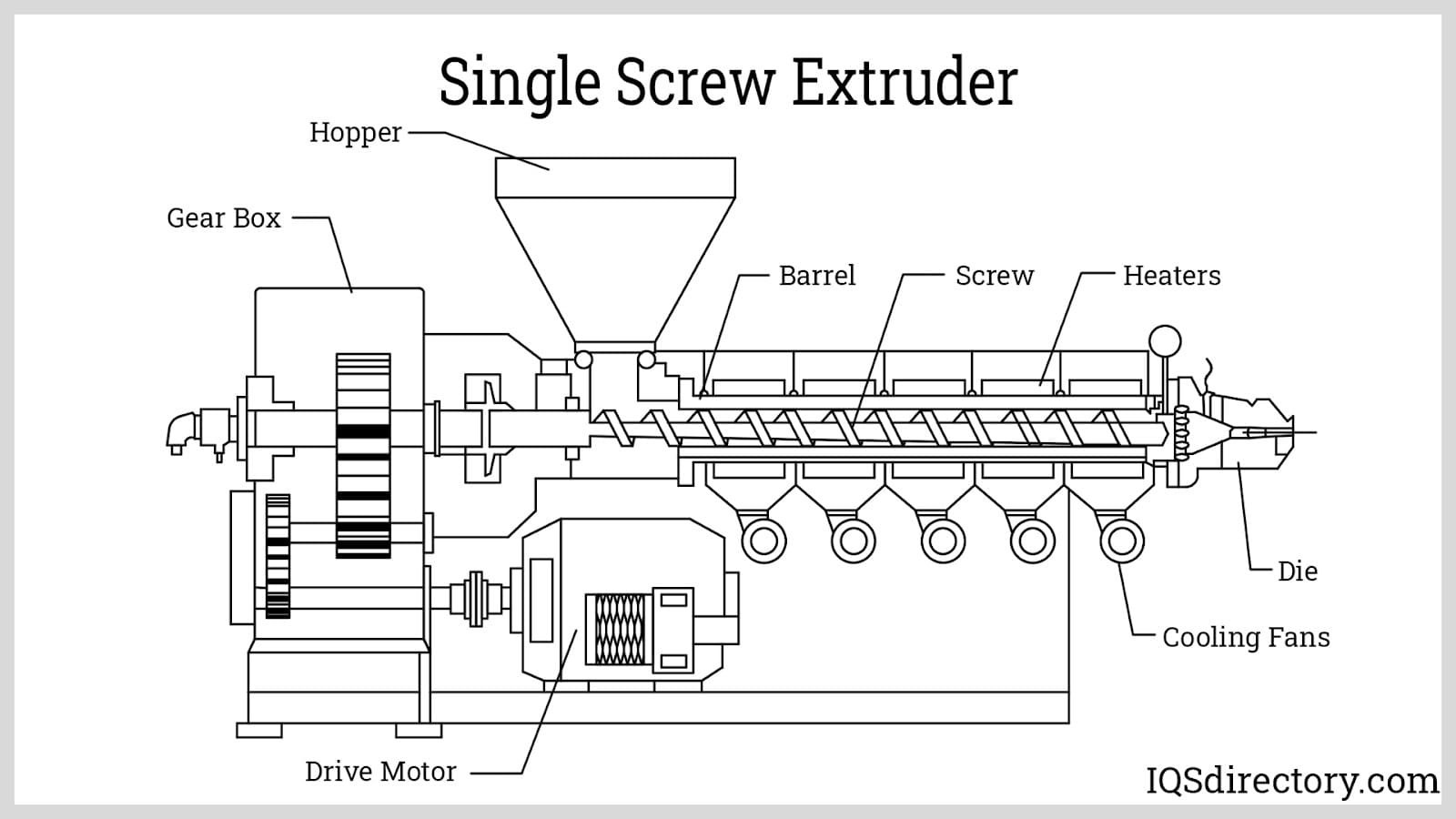

Single Screw Extruder An Overview Sciencedirect Topics

Tutorial Injection Molded Parts

Hydraulic Press Machine Parts Types Working Applications With Pdf

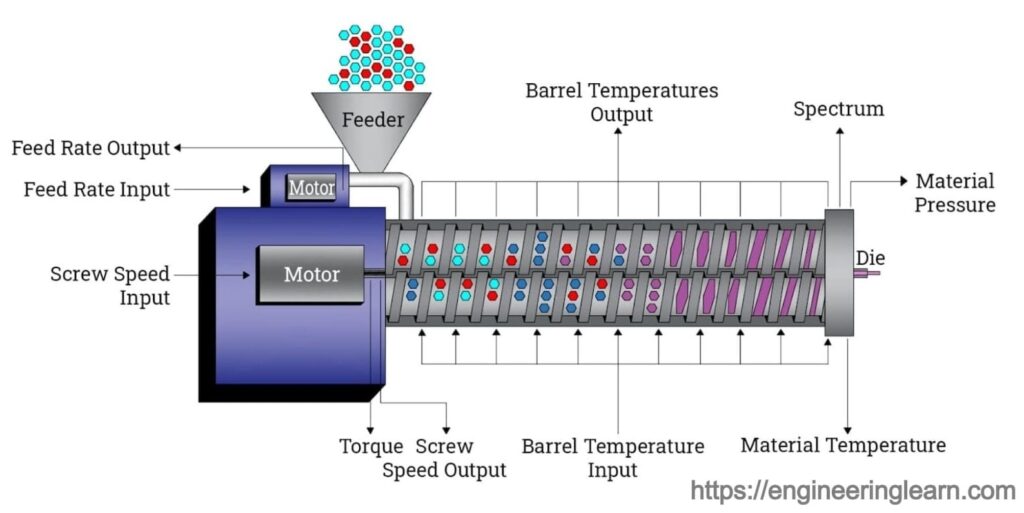

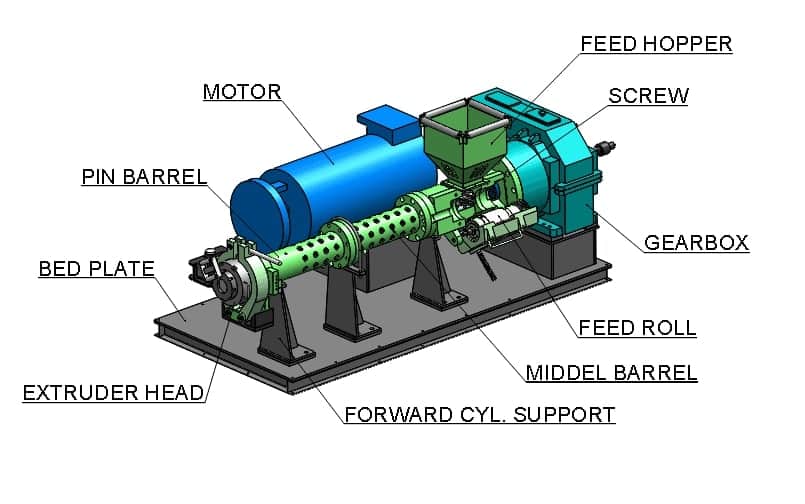

Types Of Extruders Application Working Principle Engineering Learn

What Is Melt Blown Extrusion And How Is It Used For Making Masks

Injection Molding Machine Construction Working Application Advantages And Disadvantages Custom Engineered Wheels Inc Cew

.jpg)

An Introduction To Single Screw Extrusion

Plastic The Polymers Britannica

Types Of Extruders Application Working Principle Engineering Learn